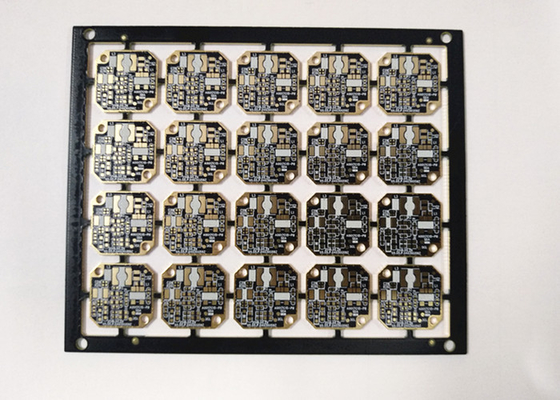

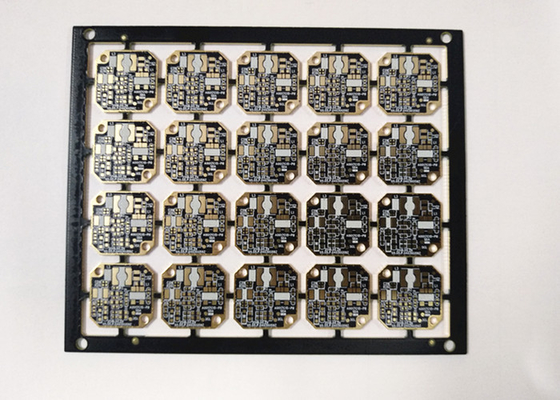

4 Layers HDI Printed Circuit Boards Black Soldermask White

Silkscreen

Features of Blue Tooth Board

- One Stop OEM Service: Made in Shenzhen of China

- Manufactured by Gerber File and Bom LIst Offered by Customers

- SMT, DIP Technology Support

- FR4 Material Meet 94v0 Standard

- UL,CE,ROHS Compliant

- Standard Lead Time: 4-5days for 2L;5-7 for 4L. Expedited Service is

available

What KAZ Circuit can do for you:

- PCB manufacturing (prototype, small to medium, mass production)

- Components Sourcing

- PCB Assembly/SMT/DIP

To get a full quotation of the PCB/PCBA, pls provide the

information as below:

- Gerber File, with detail specification of the PCB

- BOM List (Better with excel fomart)

- Photoes of the PCBA (If you have done this PCBA before)

Company Informaiton:

KAZ Circuit is a professional PCB manufacturer from China since

2007, also provide PCB Assembly service for our customers. Now with

about 300 employees. Certified with ISO9001,TS16949, UL, RoHS. We

are confident to provide you quality products with factory-directed

price within the fastest delivery time!

Manufacturer Capacity:

| Capacity | Double Sided: 12000 sq.m / month

Multilayers: 8000sq.m / month |

| Min Line Width/Gap | 4/4 mil (1mil=0.0254mm) |

| Board Thickness | 0.3~4.0mm |

| Layers | 1~20 layers |

| Material | FR-4, Aluminum, PI |

| Copper Thickness | 0.5~4oz |

| Material Tg | Tg140~Tg170 |

| Max PCB Size | 600*1200mm |

| Min Hole Size | 0.2mm (+/- 0.025) |

| Surface Treatment | HASL, ENIG, OSP |

HDI printed circuit boards, also known as microvia or μvia PCBs, are an advanced PCB

technology that enable high-density interconnections and

miniaturized electronic components.

Key features and functions of HDI printed circuit boards include:

Miniaturization and increased density:

HDI PCBs feature smaller, more closely spaced vias and vias, allowing for

higher interconnect density.

This makes it possible to design more compact, space-saving

electronic devices and components.

Microvias and Stacked Vias:

HDI PCBs use microvias, which are smaller, laser-drilled holes that are

used to connect different layers of the PCB.

Stacked vias, where multiple vias are stacked vertically, can

further increase interconnect density.

Multi-layer structure:

HDI PCBs can have a higher layer count than traditional PCBs, typically 4

to 10 or more.

The increased number of layers allows for more complex routing and

more connections between components.

Advanced materials and processes:

HDI PCBs often use specialized materials such as thin copper foil,

high-performance laminates, and advanced plating techniques.

These materials and processes enable the creation of smaller, more

reliable, higher-performance interconnects.

Improved electrical properties:

The reduced trace widths, shorter signal paths, and tighter

tolerances of HDI PCBs help improve electrical performance, including improved signal

integrity, reduced crosstalk, and faster data transmission.

Reliability & Manufacturability:

HDI PCBs are designed for high reliability, with features like improved

thermal management and enhanced mechanical stability.

Manufacturing processes for HDI PCBs, such as laser drilling and advanced plating techniques, require

specialized equipment and expertise.

HDI printed circuit board applications include:

Smartphones, Tablets, and Other Mobile Devices

Wearable Electronics and IoT (Internet of Things) Devices

Automotive electronics and advanced driver assistance systems

(ADAS)

High speed computing and telecommunications equipment

Military and aerospace electronic equipment

Medical devices and instruments

The continued demand for miniaturization, enhanced functionality,

and higher performance in a variety of electronic products and

systems has driven the adoption of HDI PCB technology.

Pictures of Products