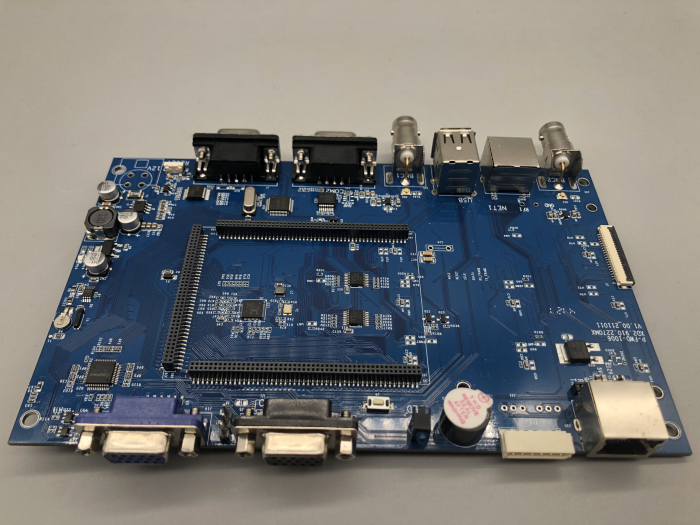

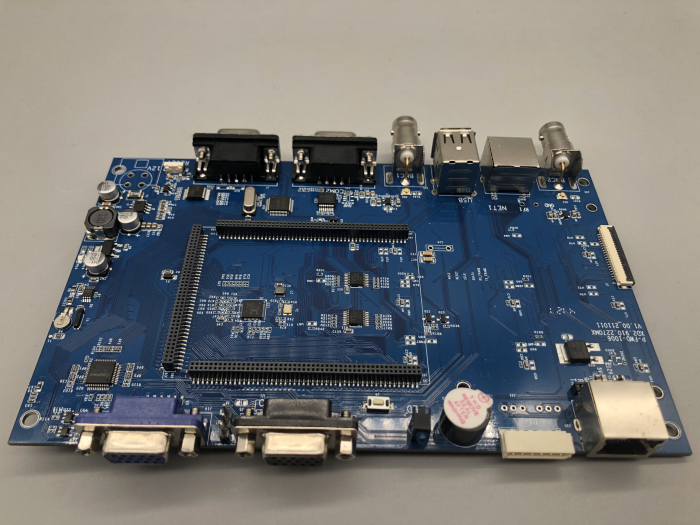

PCBA-S-096597 Smt Prototype Pcb Assembly Services Mass Production

SMT PCB Assembly

Detail Specifications:

| Layers | 4 |

| Material | FR-4 |

| Board Thickness | 1.6 mm |

| Copper Thickness | 1oz |

| Surface Treatment | HASL LF |

| Soldmask & Silkscreen | Green & White |

| Quality Standard | IPC Class 2, 100% E-testing |

| Certificates | TS16949, ISO9001, UL, RoHS |

What KAZ Circuit can do for you:

- PCB & PCBA Design

- PCB manufacturing (prototype, small to medium, mass production)

- Components Sourcing

- PCB Assembly/SMT/DIP

To get a full quotation of the PCB/PCBA, pls provide the

information as below:

- Gerber File, with detail specification of the PCB

- BOM List (Better with excel fomart)

- Photoes of the PCBA (If you have done this PCBA before)

Manufacturer Capacity:

| Capacity | Double Sided: 12000 sq.m / month

Multilayers: 8000sq.m / month |

| Min Line Width/Gap | 4/4 mil (1mil=0.0254mm) |

| Board Thickness | 0.3~4.0mm |

| Layers | 1~20 layers |

| Material | FR-4, Aluminum, PI |

| Copper Thickness | 0.5~4oz |

| Material Tg | Tg140~Tg170 |

| Max PCB Size | 600*1200mm |

| Min Hole Size | 0.2mm (+/- 0.025) |

| Surface Treatment | HASL, ENIG, OSP |

SMT Capacity

SMT PCB assemblyprocedure:

PCB Prep:

Clean the PCB substrate to remove any contaminants that may affect

solder joint quality.

Apply solder mask to the PCB to identify copper pads where

components will be placed.

A surface treatment such as ENIG (Electroless Nickel Immersion

Gold) is applied to the copper pads to promote solderability.

Solder paste print:

Place the stencil over the PCB with the stencil's openings matching

the PCB's copper pads.

The solder paste (a mixture of solder alloy particles and flux) is

scraped across the stencil, depositing the solder paste on the pads

of the PCB.

Precise control of stencil thickness, solder paste volume, and

squeegee pressure are critical for consistent solder paste

deposition.

Element placement:

Automatic pick-and-place machines use vision systems to accurately

identify component locations and place them on the solder paste.

Component orientation, coplanarity, and positional accuracy are

critical to reliable solder joints.

Additional components such as connectors or heat sinks can be

placed manually.

Reflow soldering

PCB components are passed through a reflow oven with carefully

controlled temperature profiles.

The solder paste melts, moistening the component leads and PCB

pads, and forms a solder joint as it cools.

Different solder alloys, such as lead-free (such as

tin-silver-copper), have specific reflow temperature profiles.

Inspection and Testing:

Visual inspection (manual or automated) checks for proper component

placement, solder joint quality, and potential defects.

Automated optical inspection (AOI) systems use machine vision to

quickly identify and locate any problems.

Electrical testing, such as in-circuit testing (ICT) or functional

testing, verifies the electrical performance of the PCB.

Clean and Conformal Coating (optional):

PCB assemblies may undergo a cleaning process to remove any

remaining solder paste or flux.

Conformal coating is a polymeric protective layer that can be

applied to PCBs to increase moisture and environmental resistance.

SMT PCB assembly requires strict control over the entire process to ensure high

quality and reliability of electronic products. Continuous

improvements in automation, process control, and inspection

technologies are critical to the widespread use of SMT in modern

electronics manufacturing.

Photoes of this quick turn prototype & mass production for SMT PCB Assembly 6 PCB

Assembly lines