ShenZhen KaiZhuo Electronic Technology Co.,Ltd

In the year of 2024, SHENZHEN KAIZUO ELECTRONIC TECHNOLOGY CO., LTD

(KAZ CIRCUIT) has joined Kingsum group (www.kingsumpcba.com), to seek for a larger market share from PCB manufacturing,

component sourcing, pcb assembly, and box build assembly with

better price and lead time.

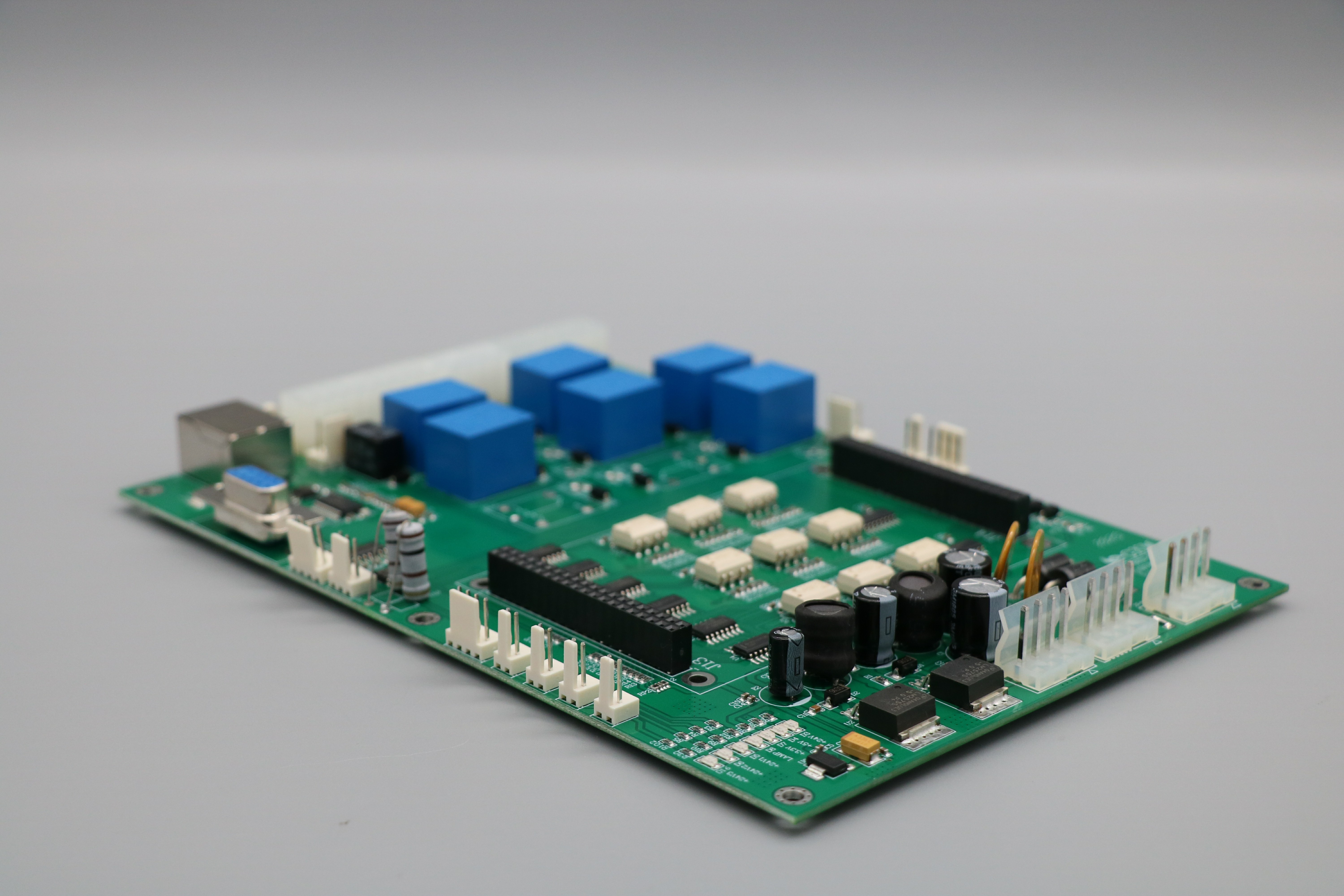

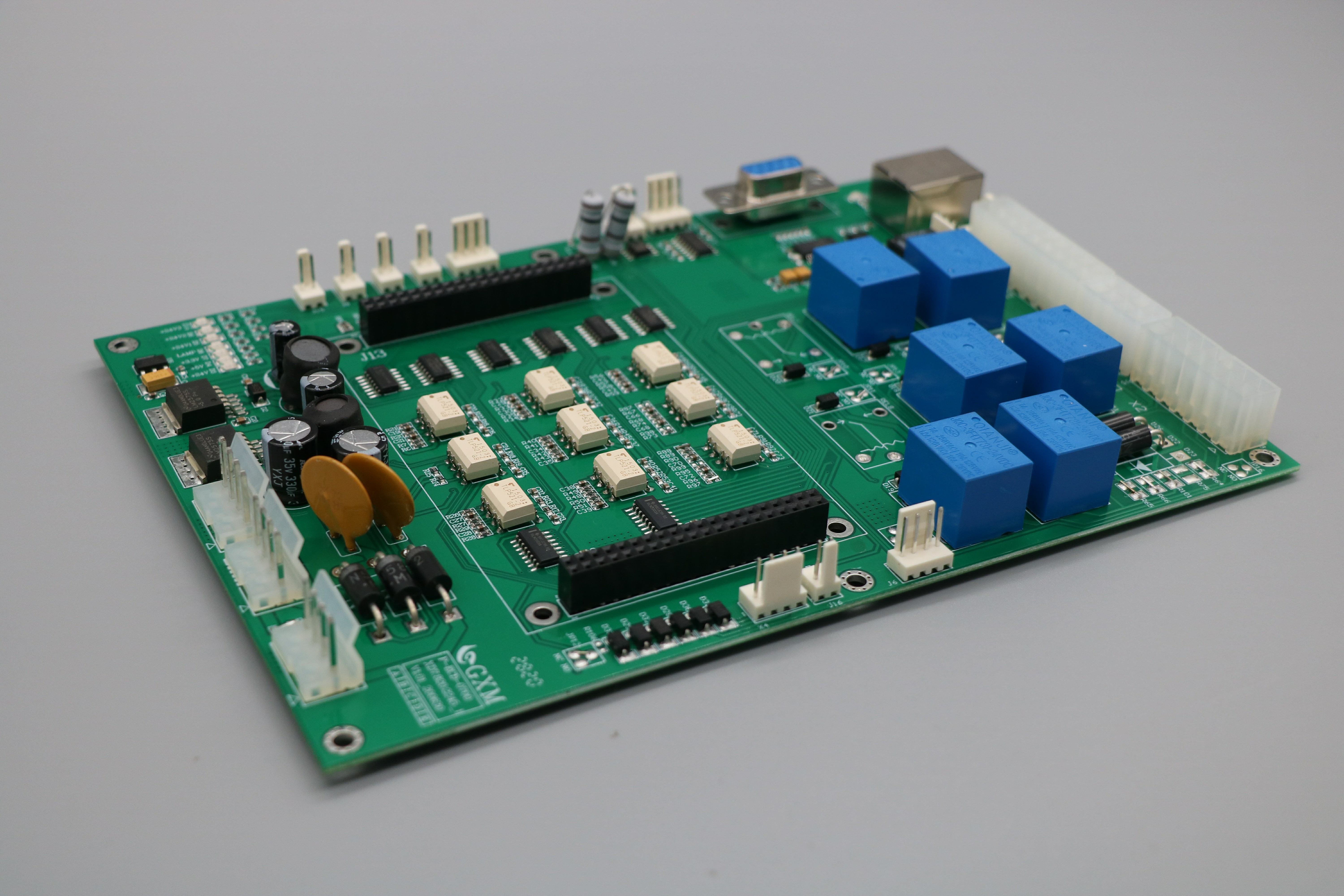

Founded in 2007, KaiZuo Electronic (hereinafter referred to as KAZ) is a professional & high quality provider of Electronic

Manufacturer Service (EMS) from China. With about 300 experienced

employees, KAZ can provide customers with one stop services

including PCB manufacturing, Components Sourcing, PCB Assembly,

Cable Assembly, Box Building, IC Programming, Functional and Aging

Testing. Certified with ISO9001, UL, RoHS, TS16949.

Equipped with 5 high-speed SMT, automatic printing machine

(DSP1008), MIRAE MX200/MIRAE MX400 high-speed production line,

YAMAHA equipment (YS24/YG12F...), reflow soldering (NS-1000), AOI

testing equipment (JTA-320-M), X-Ray inspection equipment (Nikon

AX7200), 2 DIP production lines and Nitto wave soldering.

After focusing on the electronic manufacturer services for 13+

years, KAZ has established long-term cooperated & satisfied

customers all over the world. Mainly from North America, European,

Asia and Australia. Application fields including industrial

control, IT/Networking, IoT, security, automotive, power

electronics, consumer electronics, lighting, etc.

Some of KAZ Customers:

Certificates including: