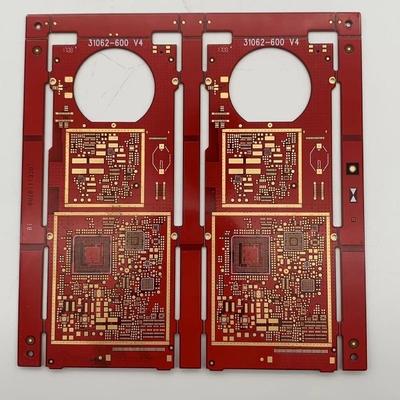

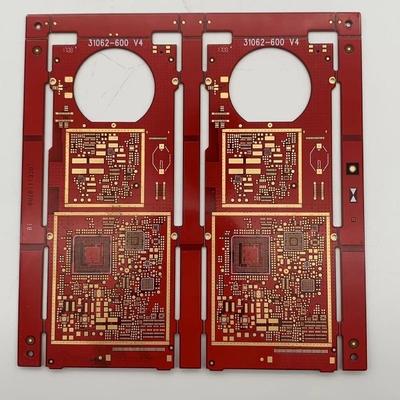

Heavy Copper PCB PCBA 4 Layers FR 4 Red Soldmask PCB Assembly

service

Detail Specifications:

| Layers | 4 |

| Material | FR-4 |

| Board Thickness | 1.6mm |

| Copper Thickness | 1oz |

| Surface Treatment | ENIG |

| Soldmask & Silkscreen | Red & White |

| Quality Standard | IPC Class 2, 100% E-testing |

| Certificates | TS16949, ISO9001, UL, RoHS |

What KAZ Circuit can do for you:

- PCB & PCBA Design

- PCB manufacturing (prototype, small to medium, mass production)

- Components Sourcing

- PCB Assembly/SMT/DIP

To get a full quotation of the PCB/PCBA, pls provide the

information as below:

- Gerber File, with detail specification of the PCB

- BOM List (Better with excel fomart)

- Photoes of the PCBA (If you have done this PCBA before)

Company Informaiton:

KAZ Circuit is a professional PCB manufacturer from China since

2007, also provide PCB Assembly service for our customers. Now with

about 300 employees. Certified with ISO9001,TS16949, UL, RoHS. We

are confident to provide you quality products with factory-directed

price within the fastest delivery time!

Manufacturer Capacity:

| Capacity | Double Sided: 12000 sq.m / month

Multilayers: 8000sq.m / month |

| Min Line Width/Gap | 4/4 mil (1mil=0.0254mm) |

| Board Thickness | 0.3~4.0mm |

| Layers | 1~20 layers |

| Material | FR-4, Aluminum, PI |

| Copper Thickness | 0.5~4oz |

| Material Tg | Tg140~Tg170 |

| Max PCB Size | 600*1200mm |

| Min Hole Size | 0.2mm (+/- 0.025) |

| Surface Treatment | HASL, ENIG, OSP |

SMT Capacity

Certifications:

ISO9001 / ISO14001 / ISO45001 (Military) / TS16949 (Automotive) /

RoHS / UL

Following are the key steps of Heavy Copper PCB Assembly Service:

Materials and Components:

High Copper Content PCB (2oz, 4oz or 6oz copper thickness)

Heavy Electronic Components (e.g. Power Transistors, High Power

Resistors, Heat Sinks)

High Temperature Solder (e.g. High Melting Point Lead-Free Solder)

High Quality Solder Paste

PCB Assembly Process:

PCB Preparation:

Clean PCB surface thoroughly to remove any contaminants.

Apply solder mask and silk screen as per component placement

requirements.

Drill and through holes for component leads and mounting.

Component Placement:

Carefully place components on PCB ensuring proper orientation and

alignment.

Secure component leads to PCB pads using high temperature solder

paste.

Reflow Soldering:

Place assembled PCB in reflow oven or use hot air rework station.

Heat PCB to appropriate reflow temperature (usually 230°C to 260°C)

to melt solder paste.

Ensure proper solder wetting and joint formation for all component

connections.

Inspection and Testing:

Visually inspect the PCB for any solder bridges, cold joints, or

missing components.

Perform electrical tests to verify the functionality of the

circuit, such as continuity, resistance, and voltage measurements.

Perform any necessary functional tests to ensure the circuit meets

design specifications.

Thermal Management:

Identify high-power components that require additional cooling.

Install heat sinks or other thermal management solutions as needed

to effectively dissipate heat.

Ensure proper thermal interface between components and heat sink.

Conformal Coating (Optional):

Apply conformal coatings, such as acrylic or polyurethane, to

protect the PCB and components from environmental factors such as

moisture, dust, and corrosion.

Final Assembly and Packaging:

Secure the PCB in a suitable housing or enclosure, if required.

Pack the assembled PCB for safe shipping and delivery.

Key Considerations for Heavy Copper PCB Assembly:

Ensure the PCB material and copper thickness are appropriate for

the power requirements of the application.

Select components with appropriate power ratings and heat

dissipation capabilities.

Use high-temperature solder and solder paste to withstand higher

operating temperatures.

Implement proper thermal management solutions to prevent components

from overheating.

Photoes of this battery chargers PCB & PCBA manufacturer FR-4 Red Soldmas